WHAT IS RESISTEEL®?

The Hardest Steel Ever Engineered for Broaching.

- Resisteel® is a revolutionary, ultra-hard steel engineered to maximize tool longevity. Traditional materials wear down quickly, leading to costly replacements.

- Resisteel® refuses to wear down. Developed over 4 years in collaboration with KU Leuven, its exact composition remains proprietary.

- This patented material is corrosion-resistant, tough, and virtually unbreakable, making it the ultimate choice for broaching blades, taps, end mills, and drills.

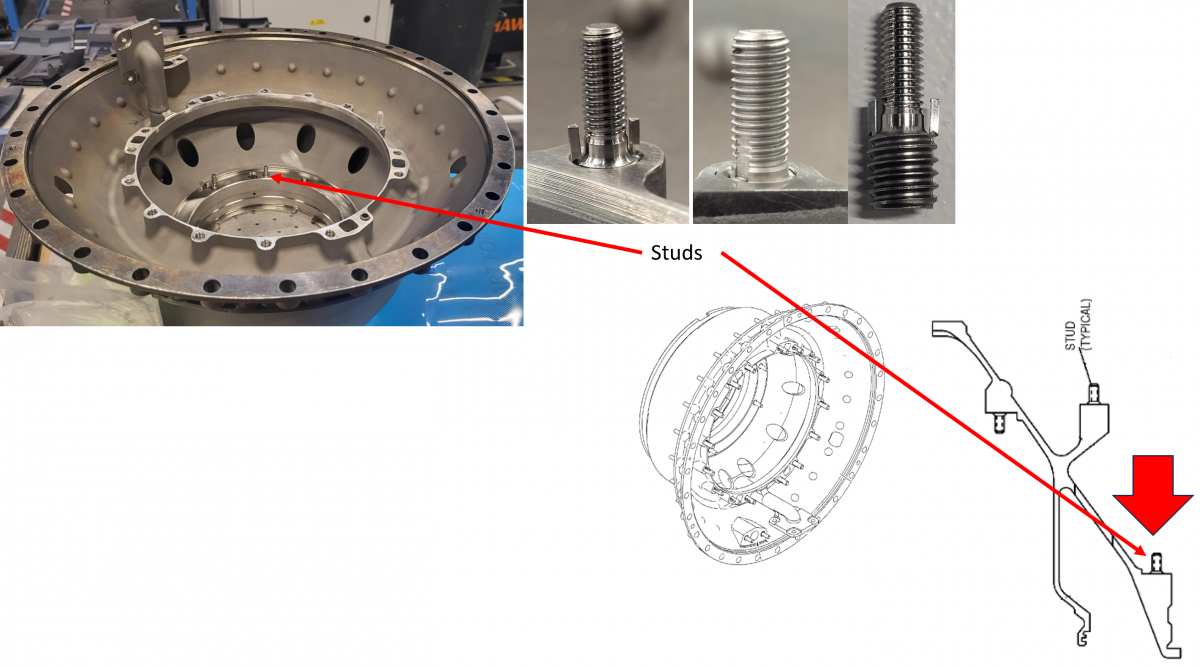

The tool shown below: BTR453-4

THE PROOF - REAL RESULTS WITH GE AEROSPACE

Resisteel® vs. Standard Broaching Tools – The Results Speak for Themselves

Case Study Summary:

Tested by GE Aerospace on the CF34-10E Engine

- Standard broaching: 1-3 cycles in Inconel 718

- Resisteel®: 156 cycles in the same conditions

- Used for repairing 3 engines, broaching 52 stud holes per engine

- Outcome: Resisteel® significantly outperformed traditional hardened or coated steel blades.

You can read more here.

50X

More Cycles

90%

Time Saving

156 Studholes

APPLICATIONS OF RESISTEEL®

Resisteel®'s unique properties make it ideal for various industrial applications beyond broaching. It excels in extreme conditions where other materials fail.

Applications List:

- Broaching Tool

- Taps & End Mills

- Drills & Cutting Tools

- High-Performance Industrial Applications

LET'S TALK PERFORMANCE

Want to know how Resisteel® can improve your tools? Get in touch to discuss your requirements and discover how Resisteel® can enhance your manufacturing process.

Or email us at: info@anemo.eu